(ATF) Production of some of Apple Inc’s MacBooks and iPads has been postponed due to the global component shortage, despite the US tech giant’s buying clout.

iPhone production has not yet been affected although the supply of some components for the devices is “quite tight”, Nikkei Asia said on Thursday.

Chip shortages have caused delays in a key step in MacBook production, the report said, adding that some iPad assembly was postponed because of a shortage of displays and display components.

Read more: US restricts trade with Chinese supercomputer centres

As a result of the delay, Apple has pushed back a portion of component orders for the two devices from the first half of this year to the second half, the report said, citing sources briefed on the matter.

The shortage of components remains a supply chain issue for Apple and has not yet impacted any product availability for consumers, Nikkei added.

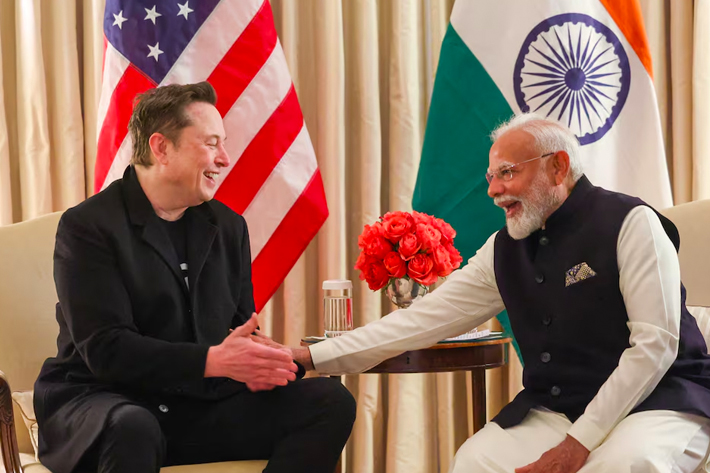

A global semiconductor shortage has disrupted car production for some of the world’s largest carmakers such as Volkswagen, Ford, Genera Motors and Honda. Tesla also shut down a Model 3 production line at its factory in Fremont, California, for two days, and Chinese electric vehicle maker Nio recently suspended production for five days.

PROFIT MARGINS

Analysts say a rise in demand for smartphones and stay-at-home technologies that offer higher profit margins has squeezed the production of automotive chips.

But now the consumer electronics industry, and even Apple, with its massive procurement power, is not immune from the unprecedented supply crunch.

“Chip shortages’ impact has expanded from the auto sector to the consumer electronics sector. The high concentration of contract chipmakers and the prolonged period it takes to expand capacity are the main reasons for the chip shortage,” Chen Xianshun and Yu Yabinbin, analysts from Guotai Junan Securities, said.

EXPANDING CAPACITY

Take the auto industry as an example, TSMC makes 70% of the world’s microcontrollers but the business accounts for less than 5% of TSMC’s revenues. The company has been focused on expanding its capacity in advanced processing techniques in the recent years, and has little flexibility in its capacity to make chips for the mature processes needed for automobiles.

During the Covid-19 pandemic, many chip makers held off expanding their production capacity and underestimated the recovery of consumer demand, resulting in a global chip shortage, the analysts said.

“The semiconductor shortage demonstrates the increasing supply chain risks amid a trend towards de-globalisation,” they added.