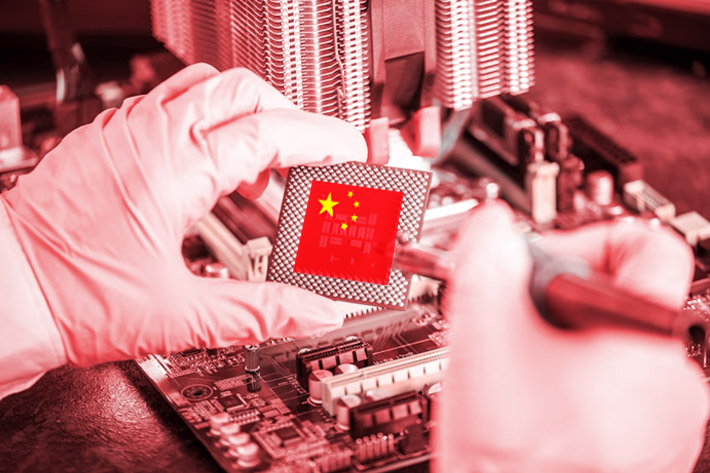

Tesla is struggling to manufacture its own state-of-the-art electric vehicle (EV) batteries, as it continues to rely on fuel cells made in China or South Korea.

Elon Musk, its chief executive, has demanded the company ramp up battery production, especially of its so-called 4680, denoting the diameter (46mm) and height (80mm).

These batteries are much larger and hold more energy than the current 2170 batteries, reducing costs. Tesla is also pioneering a cost-efficient new battery manufacturing process called dry battery electrode.

“Our focus right now is on the dozens of little issues that inhibit the production ramp of the 4680,” Musk said on a conference call on Wednesday after the company released quarterly results.

Tesla said on Wednesday it would rely on suppliers to meet battery demand this year, as the necessity of learning new technologies is holding back its plan to boost production of its own batteries.

“Time is running out and that end of the year deadline is fast approaching, meaning the company will need to work quickly to resolve the remaining issues to meet the volume they need,” Benchmark Mineral Intelligence analyst Caspar Rawles said.

Tesla Buys Batteries From Other Companies

Tesla is an outlier in its industry – it is the only major carmaker that makes batteries itself without partnering with suppliers, although like other companies, it buys batteries from other companies.

Batteries are the most expensive component in an EV and bringing down their cost is crucial to expanding the cars’ popularity.

If Tesla succeeds, it will assure itself a steadier supply of inexpensive, higher-range batteries, a foundation for its own goals of producing 20 million vehicles a year.

But it needs such new batteries next year to avoid scrambling for supplies just as the global industry scales up electric production.

In 2020, Tesla signalled it would have 100-gigawatt capacity of 4680s this year – which would be enough to supply production at new factories in Texas and Germany.

Musk said in April that Tesla’s vehicle production ramp-up would be at risk early next year if the automaker failed to solve its 4680 manufacturing issues.

- Reuters, with additional editing by George Russell

READ MORE:

Tesla Profits Upbeat as Musk Sells Off Most Bitcoin Holdings

South Korea’s Samsung SDI Sets Up Malaysia Battery Plant

Twitter Wins Bid to Fast-Track Case Against Elon Musk