Dutch engineering group Arcadis has been selected to manage the design and development programme for Wallbox’s new electric vehicle (EV) charger manufacturing factory in Texas.

Wallbox began construction of the 130,000 square foot EV charging factory in April, which will go into production in the third quarter of 2022 and is expected to produce 250,000 units in 2022. By 2025, the facility is expected to produce over 500,000 units annually.

The Washington, DC-based Wallbox’s chargers are compatible with all EVs in line with a US policy to promote compatible infrastructure.

Last month, US officials held a meeting with major automotive leaders including Tesla chief executive Elon Musk and General Motors head Mary Barra to discuss electric vehicles (EVs) and charging.

Congress last year approved $7.5 billion in government funding for EV charging stations but legislation has stalled for new tax incentives to purchase and build EVs.

“There was broad consensus that charging stations and vehicles need to be interoperable and provide a seamless user experience, no matter what car you drive or where you charge your EV,” the White House said in a statement.

The US government may need more than 100,000 charging stations to support widespread EV use, a government watchdog told a congressional hearing.

In addition to manufacturing, the Arcadis site will also feature offices, labs, evaluation areas and a warehouse, and is expected to create 250 high-paying green jobs in the region.

“Charging infrastructure and manufacturing are critical to supporting EV adoption,” Ketan Maroo, vice-president of industrial infrastructure at Arcadis, said.

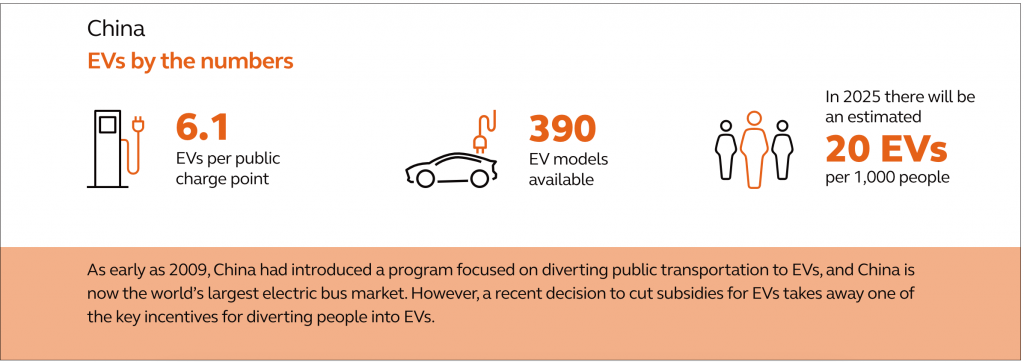

The Dutch company publishes the annual Arcadis Global EV Index. The index looks at countries across the world, particularly regions where Arcadis has been involved in mobility projects. Its China data is shown at left.

“EV adoption is essential in reducing greenhouse gas emissions and mitigating the effects of climate change,” Maroo added.

He said Arcadis has factored critical sensitivities such as humidity control and dust mitigation into the factory’s design. “The team has also identified plans for installing future solar panels and for sourcing recyclable furniture, to reduce the plant’s overall carbon footprint.”

- George Russell

READ MORE:

Advocates Urge More EV Charging in Remote Australia – ABC

Smart Charging May Be Key To Saving Power Grid In EV World

India Plans EV Charging Stations Along Highways: Mint