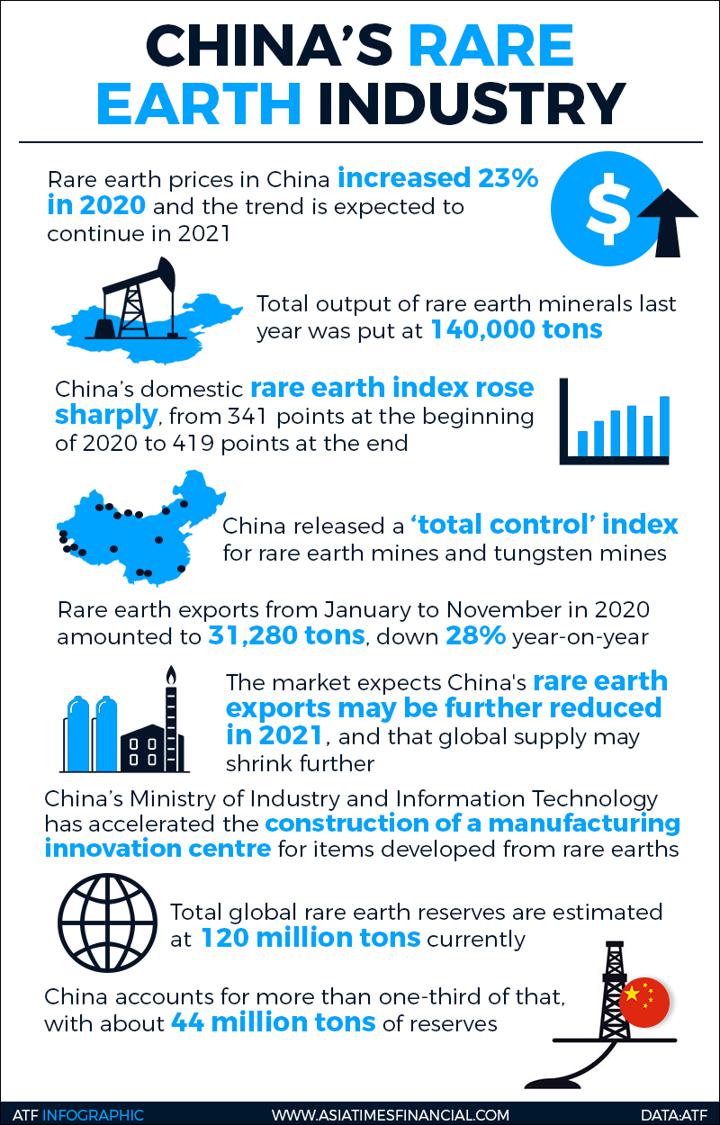

(ATF) China’s domestic prices for rare earths rose sharply in the second half of 2020, and the trend is expected to continue into 2021.

‘Rare earth’ is a general term for 17 mineral elements in the periodic table, which have seen increasing use, and have become known as “industrial vitamins”. With unique heat-resistant properties and electronic layer structure, rare earths are regarded as strategic resources by various countries and widely used in civil and military fields. From microchips and electronic car batteries to Patriot and Tomahawk missiles, rare earth products are all around us, and laboratories across the world are rushing to find new uses and patent the results.

As the world’s top supplier of rare earths in 2020, China’s domestic rare earth index rose sharply, from 341 points at the beginning of the year to 419 points at the end. That was an annual price increase of nearly 23% with prices rising sharply in the fourth quarter for both light rare earths , while prices for heavy elements hit a nine-year high.

In 2020, a ‘total control’ index for rare earth mines and tungsten mines was released, as China became more aware of the strategic value of its rare earth production. This was also done as a counter lever to US sanctions in the Sino-US trade war.

All rare earth and tungsten mines will continue to be controlled in 2021, in a bid to protect and rationally develop “superior mineral resources”, in accordance with regulations on the management of protective mining of specific minerals. The Ministry of Natural Resources and Ministry of Industry and Information Technology also issued a notice last year to order a ‘total control’ index of tungsten ore mining.

After this, total output of rare earth minerals was put at 140,000 tons. Most of this was light rare earths – 120,850 tons, plus ion-type rare earth minerals (mostly medium and heavy rare earths) totalling 19,150 tons.

National tungsten concentrate (65% tungsten trioxide) mining listed on the control index totalled 105,000 tons. The output data in 2020 is the highest year since 2014, and much is being used for China’s strategic reserves.

China’s rare earth exports fell sharply

According to official statistics, rare earth exports from January to November in 2020 amounted to 31,280 tons, down 28% year-on-year.

The ‘Export Control Law of the People’s Republic of China’ came into effect on December 1. The market expects that China’s rare earth exports may be further reduced, and that global supply may shrink further and become even more tight. Other countries, such as the US, Australia and Russia are scrambling to open new mines, but even after finding new sources, China is far advanced in rare earth processing.

Decentralization of some mining rights, approvals

On April 17, the Ministry of Natural Resources issued an announcement stating that from May 1, oil, hydrocarbons, natural gas, shale gas, natural gas hydrates, radioactive minerals, tungsten, rare earths, tin, antimony, molybdenum, cobalt, mineral resources, plus 14 important strategic minerals such as lithium, potash, and crystalline graphite would be transferred and overseen by local governments.

This means that follow-up registration of 11 minerals of coal, coal bed methane, iron, chromium, copper, aluminum, gold, nickel, zirconium, phosphorus, and fluorite will be handled by provincial natural resources authorities. For other prospecting rights, mining rights, and approved trial mining and approved mining areas, follow-up registration items shall be handled by the natural resources department at or below the provincial level in administrative regions.

Innovation centre set up

In order to implement General Secretary Xi Jinping’s instructions on the development of the rare earth industry, the Ministry of Industry and Information Technology is promoting innovation on the use of resources and has sped up the construction of a manufacturing innovation center for items developed from rare earths.

Recently, Guorui Kechuang Rare Earth Functional Materials Co Ltd got approval to establish a National Rare Earth Functional Materials Innovation Centre. New innovative products such as fluorescent glass and magnets for use in electric vehicles have already emerged.

The Innovation Centre was jointly organized by the Inner Mongolia Autonomous Region’s Industry and IT Department and Jiangxi Province’s Industry and IT Department to bring businesses in the north and south together along with universities.

A construction plan has been approved and the Innovation Centre will focus on magnetism, luminescence, catalysis, alloys and other functional materials, rare earth secondary resource recycling and other fields, focusing on the integration of high-end rare earth functional materials design, processing, and manufacturing technologies, plus key technologies for mass preparation of new rare earth materials.

They hope to develop cutting-edge materials and technologies at the innovation platform by integrating research and development, pilot incubation and test verification to accelerate breakthroughs in functional materials and enhance industrial innovation capabilities. This is part of plans for China to be a high-tech manufacturing power.

Resource tax law

China’s ‘Resource Tax Law’ was implemented on September 1, 2020. It clearly stipulates that strategic resources such as crude oil, natural gas, medium and heavy rare earths, tungsten and molybdenum are subject to fixed tax rates. Others are determined by local governments within a legal tax rate range.

The tax rate range for coal is 2-10%, while the tax range for ferrous metals is 1-9%, and the tax range for light rare earths is 7-12%.

There are fixed tax rates for crude oil, natural gas, tungsten, molybdenum, medium and heavy rare earths, uranium, and thorium. For example, the crude oil tax rate is 6%, the natural gas tax rate is 6%, tungsten is 6.5%, molybdenum is 8%, and medium and heavy rare earths are 20%.

Largest producer, exporter of RE magnet materials

Rare-earth permanent magnet material is made of alloy composed of samarium, neodymium mixed rare earth metal and a transition metal such as cobalt or iron, pressed and sintered by powder metallurgy, and magnetized by a magnetic field. Compared with traditional permanent magnets, rare earth permanent magnet materials now have the best magnetic properties and overall performance. They have become an indispensable basic for modern industry. China has abundant rare earth resources and has become the largest production and export base for rare earth permanent magnet materials.

In 2019, the output of NdFeB permanent magnet materials in China was 180,300 tons, a year-on-year increase of 9.6%. The rapid growth of NdFeB permanent magnet materials is due to the downstream electronic information manufacturing industry and other needs.

Sector wants standardised pricing, but process needs improvement

China’s ambition is to be the global hub for the rare earth trade. Today, Baotou City in Inner Mongolia is “the capital of rare earths”, and companies there have formed a large number of application products with independent intellectual property rights in the fields of aerospace, magnetic refrigeration, permanent magnet motors, hydrogen storage batteries, energy saving and environmental protection.

But the fluctuating prices of raw materials has caused frustration among many rare earth companies. Jin Shusen, chairman of Baotou Jinshan Magnetic Materials Co Ltd, said that to solve the problem of fluctuating prices, a method of dredging and blocking could be adopted. The total amount of rare earth mines should be increased, and the capacity for smelting and separation further improved, and combined with a crackdown on wildcat digging.

From a development point of view, the continuous improvement of shortcomings and use of newly launched electronic trading platforms in 2020 recognized by all parties will help further improve the price formation mechanism. However, the current system design, corporate governance, transaction mode and other issues still need to be upgraded to meet the needs of market transactions for all parties. And due to the small scale of the rare earth market, it is difficult to avoid speculation and stabilise market expectations. So the government is looking at these things because it wants to promote steady development of the rare earth market.

In addition, the China Rare Earth Industry Development Index was officially released in Baotou early this year. This index, together with the previously China Rare Earth Price Index and China’s Rare Earth Industry Prosperity Index, make up the China Rare Earth Series Index, which provides big data solutions for the industry at both micro to macro levels. It acts as a “barometer” for the development of China’s rare earth industry.

Li Zhenhong, chairman of Baotou Rare Earth Products Exchange, said the country has attached great importance to the development of the industry for many years and has issued a number of management measures and supporting policies. The rare earth market’s price formation mechanism still lacks innovation, but the use of exchanges is seen as one way to improve this and to influence global commodity pricing.

Yang Wenhao, secretary-general of the China Rare Earth Industry Association, said information irregularities and the different demands of stakeholders had affected healthy and sustainable development of the sector to a certain extent. All parties are exploring effective ways to tackle these issues.

“In the future, China’s rare earth series indexes will be further optimized and perfected in indicator construction, calculation and analysis, which will be stable and long-term, and will better play the role of a ‘weather vane’ to provide more services for the development of China’s rare earth industry,” Yang Wenhao said.

Japan plans to substantially increase rare earth reserves

The Japanese government aims to strengthen the rare metal reserve system required for industrial products such as electric vehicles. At present, Japan’s rare metal reserves are guaranteed for 60 days of domestic consumption, and the plan is to expand reserves to more than six months in the future.

Rare metals are indispensable to Japan’s cutting-edge industries, but they are currently heavily dependent on rare earths from countries such as China. Almost all rare metals needed by industry are imported in Japan. For example, about 60% of rare earths needed for electric car engine magnets are imported from China. Statistics from Japan’s Ministry of Economy, Trade and Industry revealed that in 2018, 58% of rare metals were imported from China, along with 14% from Vietnam, 11% from France, and 10% from Malaysia.

Kyodo News reported that Japan’s 60-day rare metal reserve system was set up in 1986. The Suga government is prepared to adopt a more flexible way to reserve rare metals.

Also, although some rare metals are produced in Africa, they need to be refined by Chinese companies. So, the government intends to allow the Japan Petroleum, Natural Gas and Metals and Mineral Resources Agency to invest in a refinery, or to promote investment guarantees so that Japanese companies can obtain financing to set up facilities.

US lawmakers seek to reduce foreign dependence

Members of both parties in the US House of Representatives jointly submitted a bill last year to reduce dependence on imported rare earths. It was proposed by Republican Congressman Lance Gooden and Democrat Vicente Gonzalez from Texas, co-sponsored by Senator Ted Cruz, who made made similar proposals in May.

The bill is part of Congress’ strategy to improve raw materials, especially industrial raw material supply chains that are important for national defense. The aim is to reduce dependence on imports and get companies doing this in the US. This effort has received extensive support from local rare earth companies.

Pini Althaus, CEO of USA Rare Earth, which is developing the Round Top rare earth deposit, said in a telephone interview that tax incentives could play a vital role, as they need to cut production costs for domestic rare earth projects, from mineral mining to the creation of permanent magnets, and to improve the international competitiveness of rare earth companies.

The US has a long way to go

The Department of Defense has just provided financial support to two companies that plan to build rare earth separation plants in the United States. This is a small step towards achieving the Trump administration’s goal of eliminating dependence on imports of key minerals.

However, the direct involvement of the Pentagon exposed the difficulty of the US building a rare earth supply chain from scratch. According to statistics from the US Geological Survey, consumers of rare earth compounds and metals were almost entirely dependent on imports in 2019, and this has not changed over the years.

With the deterioration of ties with Beijing, the high degree of foreign dependence on civilian and military rare earths has caused concern in the United States. But it has learnt that a series of measures are needed to change this – direct government support, alliances with other countries, and long-term meticulous construction of a six-stage process from ore to rare earth magnets.

Total global rare earth reserves are estimated at 120 million tons currently, and China accounts for more than one-third of that, with about 44 million tons of reserves.