(ATF) China strives to strengthen self-sufficiency of chips by matchmaking automakers and suppliers and stockpiling chipmaking machines as the global shortage of computer chips forces auto plants to halt production. However, analysts expect the disruption to auto production to continue until at least the third quarter.

While Covid-19 has disrupted chipmaking around the world, a 7.1 magnitude earthquake near Japan’s northeast coastal prefecture of Fukushima and winter storm blackouts that struck the US semiconductor hub Texas last month only exacerbated the situation. Several chipmakers such as Infineon, NXP, and Samsung halted their chip production in Austin, Texas, and Japan-based Renesas Electronics closed its plant.

The world’s largest carmakers such as Volkswagen, Ford, General Motors, and Honda as well as China’s Changan Auto are bracing for production disruptions from chip shortage. Tesla also shut down a Model 3 production line at its factory in Fremont, California, for two days amid an industry-wide microchip shortage.

As China became the world’s first economy to recover from the pandemic, its auto sales also outperformed global sales in 2020. However, January auto sales decreased 11.6% month-on-month to 2.5 million units while auto production was down 15.9% from the previous month, according to the data from China Association of Automobile Manufacturers (CAAM).

Excluding years 2017 and 2020 when auto production decreased exceptionally in January, the slowdown this year is larger compared with the years 2016, 2018 and 2019, CAAM said.

Li Shaohua, secretary-general of CAAM, said chip shortage was one of the key factors that caused car production to drop in January.

A rise in demand for smartphones and stay-at-home technologies that offer higher profit margins has also squeezed the production of automotive chips, according to Li.

Amid an industry-wide chip shortage, Chen Hong, chairman of SAIC Motor and a deputy to the National People’s Congress, has called for more policy support for a self-sufficient supply chain of automotive-grade chips.

He suggests that Beijing provide research grants and subsidies for automotive chip development and production, and that insurers develop product liability insurance policies for the chips.

China, which accounts for 30% of the world’s car sales, only produces less than 5% of the world’s automotive chips.

MIIT matchmaking bid to boost chip supply-chain

Last Friday, China’s Ministry of Industry and Information Technology (MIIT) held a workshop with automakers and semiconductor companies and released a directory for supply-demand matchmaking in a bid to strengthen the domestic chip supply chain, a statement by the MIIT said.

Compiled based on a survey that the MIIT launched in June 2020 with automakers, component manufacturers, and chipmakers, the directory includes information on over 500 chip products provided by 59 semiconductor companies. They include computing chips, control chips, power chips, memory chips, communication chips, among others, and cover 80% of the types of chips needed for auto production.

The directory also includes over 1,000 listings of demand information from automakers such as China FAW Group, SAIC Motor, BAIC Motor, and BYD Auto as well as auto part companies such as Desay SV Automotive and CATL.

Qiao Yueshan, director of the Electronic and Information Department of the MIIT, said chip shortage since the fourth quarter of last year highlights the insufficient supply capacity of China’s automotive semiconductor industry.

Domestic semiconductor companies are less experienced in developing and marketing their products to the auto industry, and the directory is intended to facilitate collaboration across the supply chain, he said.

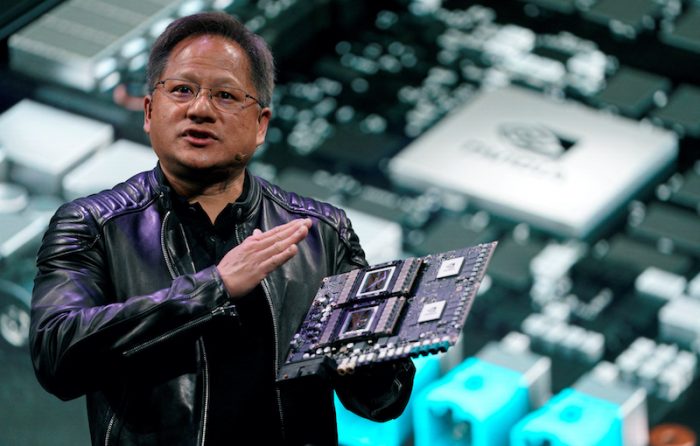

Old chip machines being snapped up

In a bid to produce homegrown chips, Chinese semiconductor makers are snapping up used chipmaking machines, driving up equipment prices in Japan’s secondary market.

A report by Nikkei Asia on Sunday said machines “worthless several years ago” now sell for $1 million.

China’s official trade data show that Chinese businesses bought almost $32 billion of equipment last year used to produce computer chips from Japan, South Korea, Taiwan and elsewhere, a 20% jump from 2019.

Meanwhile, Li from CAAM expects chip shortage to continue crippling China’s auto production for another six months. “The sales and production of cars are expected to recover in the second half, which will gradually offset the decrease in the first half,” he said.

However, David Zhang, an auto analyst with a Ministry of Industry and Information Technology-affiliated think tank, believes the market has over-panicked about chip shortage.

“There has not been a price surge in China’s auto market, which indicates that supply is enough to meet demand. Besides, the majority of cars sold in China are traditional models that have no screen or small screens, which need fewer chips,” he said.

US chip ban on Huawei

A widening US technology ban has exposed the vulnerability of China’s semiconductor sector.

After the previous US Trump administration enforced a ban on Huawei last year, preventing it from buying chips from American suppliers and later on suppliers like Taiwan’s TSMC that use American technology, the Chinese tech giant’s smartphone sales dropped 43% year-on-year in the fourth quarter.

After that, China’s largest chipmaker, SMIC, was also added to an export control blacklist by Trump, which restricts its access to chipmaking equipment for advanced nodes that are 10-nanometer and below. SMIC does not yet mass produce chips that are below 10nm, but the US sanctions will hamper its ability to develop advanced chips to meet upcoming demand.

China, a market with 28 million units of auto sales per year, imports over 80% of key components needed for auto production, according to a research report by Roland Berger released in September.

“The automotive semiconductor industry is highly concentrated, and dominated by companies like Texas Instruments, Infineon, NXP, Renesas Electronics, and Samsung. There are very few Chinese companies that can provide automotive-grade chips that are crucial to the car’s safety, such as those used for the engine control unit. Though many semiconductor start-ups have emerged, it will be unlikely for them to increase their global market shares in a short-term,” Zhang said.

A few Chinese companies such as NavInfo Co Ltd and Horizon Robotics have launched automotive-grade semiconductors for autonomous driving, but they rely on contract chipmakers such as TSMC to make the chips.

In order to stabilise the supply chain, Chinese automakers such as BYD Auto have developed their own semiconductor capability. BYD Auto set up its own semiconductor company in 2004. launched China’s first homegrown Insulated Gate Bipolar Transistor (IGBT) chip in 2009 and the first 32-bit microcontroller chip 2019.

BYD Auto said in December that its homegrown chips are sufficient for its own use, and there are extra that can be provided to other automakers.

There is only one Chinese company – namely Nexperia – among the world’s top 20 automotive semiconductor companies, according to Roland Berger’s report.

Given China’s semiconductor sector is almost two generations behind, it may take Chinese companies three to four years to catch up with the global leaders, and with a widening US technology ban the outlook does not look rosy, Zhang said.