The cars are rolling out of the automaker’s factories again – however there are still bumps in the road ahead for the vehicle giant with Covid remaining a threat to chip supplies. And it’s behind the pack in the EV race too…

Legendary US automaker Ford has restarted production of several models after a two-week hiatus due to the ongoing global semiconductor shortage, the company said earlier this week.

Its Dearborn, Michigan, truck plant and its Kansas City, Missouri, assembly plant resumed operations on Monday. Both plants produce the steel-and-aluminum-intensive F-150 pickup truck.

Ford’s Kansas City plant also restarted production of its Transit van, while its Chicago, Illinois, assembly plant, which makes the popular Explorer SUV, Police Interceptor Utility and Lincoln Aviator SUV’s, also restarted full production.

Also on AF: India-UK open cleantech two-way street of investment, green opportunity

A recent two-week closure at Ford’s Flat Rock, Michigan, plant, which produces the Mustang and the Lincoln Continental sedan, has also swung back into operation. Ford also restarted production at its Otosan van plant in Turkey.

Long-time rival General Motors (GM), also largely impacted in recent weeks due to the global semiconductor crunch, will reportedly increase output of its Chevrolet Silverado and its GM Sierra, both which are full size pick-ups, by around 1,000 units per month starting in mid-July, GM said.

Shipments of the Chevrolet Colorado and GMC Canyon midsize pick-up trucks will increase by some 30,000 units from mid-May through to July 5 as vehicles that had been partially built are fully fitted with semiconductors.

While both legacy automakers battle for not only increased US market share but also abroad, Ford is in the midst of rebranding itself as a modern automaker by pivoting to electric vehicle (EV) manufacturing after years of market contraction.

BATTERY HOOK-UP

In late May, Ford and Seoul-based battery maker SK Innovation said it would push ahead with plans to work together to manufacture battery cells for EVs in the US.

The two companies signed a memorandum of understanding in late May for a joint venture (JV) to be called BlueOvalSK. Production of the battery cells, as well as supporting modules, are expected to start by mid-decade.

Ford’s marked EV pivot came only recently after current CEO Jim Farley took over from his predecessor Jim Hackett last October. Hackett had said that Ford saw “no advantage” in producing battery cells. As such, Ford is playing catch-up to GM, which recently announced its second $2.3 billion Ultium plant in the US to produce battery cells through a JV with Korea-based LG Chem.

After announcing first quarter results in April, Farley said things had changed as the automaker boosts its EV volumes. “We’ve totally entered a different zone… so we’ve already made the decision to vertically integrate the company,” he said.

EV REBRANDING

Ford has ramped up its pro-EV game even more by vowing to make EVs some 40% of its global sales by 2030, as well as investing an additional $8 billion through 2025 in developing them, bringing its total to about $20 billion.

Ford’s stock has also trended upward by as much as 73% since the start of the year amid its EV rebranding ambitions.

Ford also said on Thursday that its adjusted pre-tax earnings for the second quarter will “surpass its expectations” and be significantly better than a year earlier, while net income will be “substantially lower” than the same period last year, when results included a $3.5 billion gain in an investment in its self-driving Argo AI unit with Volkswagen.

The company reported a net profit of $1.1 billion during the second quarter of last year.

COVID CASES

“The improvement in automotive is being driven by lower-than-anticipated costs and favourable market factors,” the company said. A day earlier, GM said it expected adjusted pre-tax earnings of some $8.5 billion to $9.5 billion for the first half of the year, up from an estimated $5.5 billion.

However, due to the increase in Covid-19 cases in Asia, especially Taiwan, a significant hub for chip production, the ongoing semiconductor shortage could be exacerbated, according to a new Wall Street Journal report.

Cases in the island nation of some 24 million people have been on the rise since early May, jumping from single to three-digit figures in just a matter of days.

WORKERS QUARANTINED

For the June 4-17 period, Taiwan experienced 3,610 new coronavirus cases, pushing the country’s overall infection count since the start of the pandemic to just under 14,000, government figures indicated.

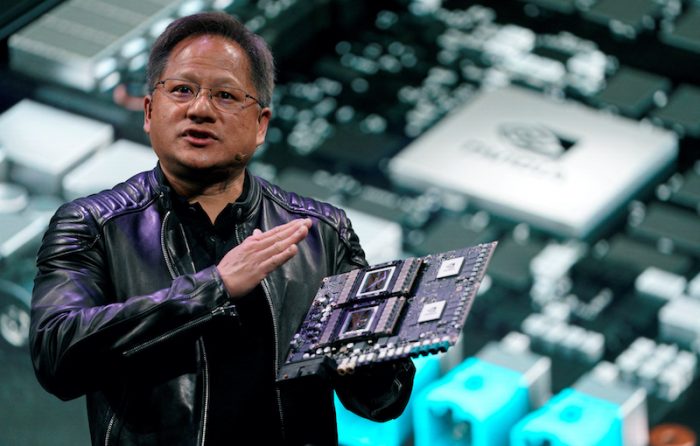

For its part, Hsinchu-based semiconductor giant TSMC, with a US$617.8 billion market capitalisation, that makes chips for Apple, Qualcomm and many other tech companies, said it had not yet been affected by the increase in Covid cases.

However, Yuan Electronics Co, one of Taiwan’s largest chip testing and packaging companies, has been impacted. More than 200 of its employees have tested positive for the virus so far this month, while another 2,000 workers have been placed in quarantine, cutting the company’s revenue this month by roughly a third.

Read more:

China urged to develop own smart car operating system

Tesla fighting its way out of the dragon’s den