Taiwan’s Foxconn is poised to accelerate its move into electric vehicle manufacturing as it looks to ‘catch the wave’ and stay ahead of its tech rivals.

The Apple contractor is now looking for that first big contract to launch its EV business, analysts say, as it has already pulled together much of the supply chain needed to produce electric cars.

But the Taiwanese contract manufacturer faces stiff competition in the market for creating white-label EVs that can be tailor-made for clients, whether that’s a major automaker or a delivery provider or any other company.

Foxconn, formally called Hon Hai Precision Industry Co Ltd, will provide an update on its EV manufacturing business when it reports its results on March 15.

Also on AF: 13 Chinese Cities Issue Smog Alerts as Factory Output Climbs

The firm has already constructed a specialised supply chain, including chips and batteries, and has acquired the former General Motor Co plant in Lordstown, Ohio. It has also hired a former Nissan executive, Jun Seki, to lead its efforts.

That US plant purchase means Foxconn can offer customers access to US federal incentives under the Inflation Reduction Act, Daiwa Capital Markets analyst Kylie Huang said.

That’s a selling point as traditional automakers juggle building gasoline-powered vehicles with plans to build their own EV capacity.

“If they don’t get one this year, next year will be more difficult,” Huang said of Foxconn’s search for an EV contract with a traditional automaker.

Failure to “catch this wave” could force Foxconn to vie with lower-tier Chinese automakers who might switch to EV contract manufacturing and compete on cost, Huang added.

Canada’s Magna International, a top auto supplier, already builds cars for others, and China’s Geely has expressed interest. China’s Guangxi Automobile Group has started to make EVs on contract for Japanese delivery company, Sagawa Express Co.

Foxconn’s ‘Android’ EV Plan

Foxconn is counting on its Mobility in Harmony EV platform, or MIH, to win customers. It calls MIH “the Android system” for EVs and is soliciting partners in an effort to standardise technologies so model variants can be developed quickly and cheaply.

“We want to create that kind of ecosystem so anyone, for example, like United Airlines, can say, ‘I want to make a car,'” Foxconn chief product officer Jerry Hsiao told Reuters during a tour of the company’s sprawling Ohio plant.

Hsiao also worked on the first Android phone for Google and now sees EVs at a similar commercial inflection point.

Foxconn are initially targeting 5% of the global EV market and the equivalent of $33 billion in revenue from manufacturing EVs and components by 2025, Foxconn’s longer-term goal is to make nearly half the world’s EVs.

EV sales have been rising, led by China. Five percent of the market, assuming an EV adoption rate of about 20% by 2025, would be around 900,000 vehicles, roughly what market-leader Tesla sold in 2021.

“In the EV market, everyone’s eyes are bigger than their stomach,” said Sam Fiorani, vice president at AutoForecast Solutions.

Tesla Raising EV Stakes

His firm estimates Foxconn hitting about 65,000 vehicles in 2025 and 157,000 in 2026. “They’re not making iPhones here,” he said.

EV outsourcing will reach $36 billion in 2025 and $144 billion in 2030, with 800,000 and 3.2 million EVs, respectively, Goldman Sachs estimates.

The race for volume in an industry where Tesla and other EV makers are cutting prices raises the stakes.

The former GM plant in Ohio that Foxconn purchased from Lordstown Motors is one of the highest volume single-line vehicle assembly plants in the world. It could build about 320,000 vehicles a year.

Foxconn wants to build around 300,000 EVs at the plant, Ian Upton, director of production control at Foxconn Ohio, told Reuters.

“We would love to find a customer that’s in the 250,000-or-so range and then we can fill up some of the other stuff with niche type things,” he said.

- Reuters with additional editing by Sean O’Meara

Read more:

Apple Supplier Foxconn Speeds up India Expansion in China Shift

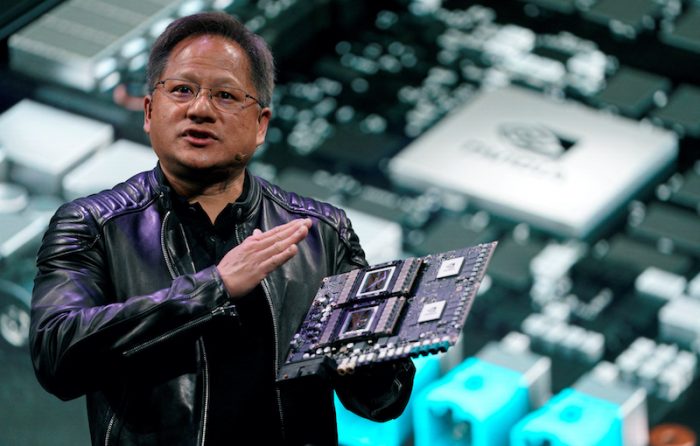

Foxconn to Use Nvidia Chips for Driverless Cars, EVs

Indonesia’s Indika and Foxconn Mull EV Batteries with Thais