Samsung Electronics said it has begun mass production of chips with advanced 3-nanometre technology as it seeks new clients to catch up with far bigger rival Taiwan Semiconductor Manufacturing Co (TSMC) in contract chip manufacturing.

The first-generation 3-nanometre process can reduce power consumption by up to 45% when compared with conventional 5-nanometre chips, boost performance by 23% and reduce area by 16%, Samsung said.

Samsung did not name clients for its latest foundry technology, which supplies made-to-order chips such as mobile processors and high-performance computing chips, with analysts saying Samsung itself and Chinese firms are expected to be among initial customers.

TSMC is the world’s most advanced foundry chipmaker and controls about 54% of the global market for contract production of chips, used by firms such as Apple and Qualcomm which don’t have their own semiconductor facilities.

Samsung, a distant second with a 16.3% market share, according to data provider TrendForce, announced a 171 trillion won ($132 billion) investment plan last year to overtake TSMC as the world’s top logic chipmaker by 2030.

“We will continue active innovation in competitive technology development,” Siyoung Choi, head of foundry business at Samsung, said.

Foundry Business Scouts For Clients

Samsung co-chief executive Kyung Kye-hyun said earlier this year its foundry business would look for new clients in China, where it expects high market growth, as companies from automakers to appliance goods manufacturers rush to secure capacity to address persistent global chip shortages.

While Samsung is the first to production with 3-nanometre chips, TSMC is planning 2-nanometre volume production in 2025.

Samsung is the market leader in memory chips, but it had been outspent by frontrunner TSMC in the more diverse foundry business, making it difficult to compete, analysts said.

“Non-memory is different, there’s too much variety,” Kim Yang-jae, an analyst at Daol Investment & Securities, said.

“There are only two kinds of memory chips – DRAM and NAND flash. You can concentrate on one thing, raise efficiency and make a lot of it, but you can’t do that with a thousand different non-memory chips.”

Samsung’s compound annual growth rate of capital spending between 2017 and 2023, which measures how quickly a company is increasing its investment, is estimated at 7.9%, versus TSMC’s estimated 30.4%, according to Mirae Asset Securities.

Samsung’s efforts to compete with the industry leader have also been hampered by less-than-expected yields of older chips during the past year or so, analysts said. The company said in March that its operations have shown a gradual improvement.

- Reuters with additional editing by Jim Pollard

ALSO READ:

Samsung Puts High Hopes on Chips, Components Units

Samsung To Supply Advanced Auto Chips To Volkswagen

Samsung Won’t Hand Over Sensitive Data To US Chips Probe

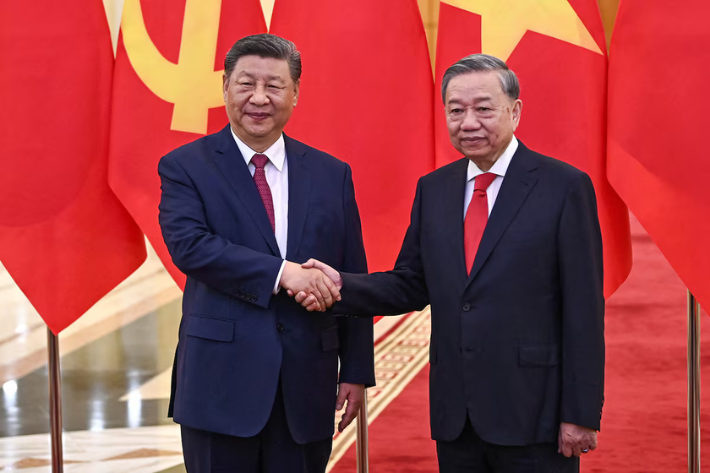

China War Risk Sees Taiwan’s TSMC Moving Fabs to US, Japan

China Must Seize TSMC if US Imposes Sanctions: Top Economist