Japanese automotive giant Toyota said it would deploy quantum computing to develop the next generation of electric vehicle (EV) batteries.

The company will tie up with Tokyo-based QunaSys to perform simulations to determine the properties of a wide range of materials.

The research will employ the density functional theory (DFT) that models the electronic structure of a material. Toyota and QunaSys will research ways to improve the DFT method through the use of quantum computers, the companies said.

The technique will lead to accelerated development, the companies added, noting that conventional supercomputers can require months to make simulations using the approach and often simulations cannot be performed because of a lack of accuracy.

“The quantitative algorithm can accurately calculate the behaviour of batteries, which makes it possible to accurately simulate the dynamic behaviour of various functional materials, realising a carbon-free society,” QunaSys said in a statement.

“It is expected that this will lead to the development of more advanced materials such as batteries and fuel cells.”

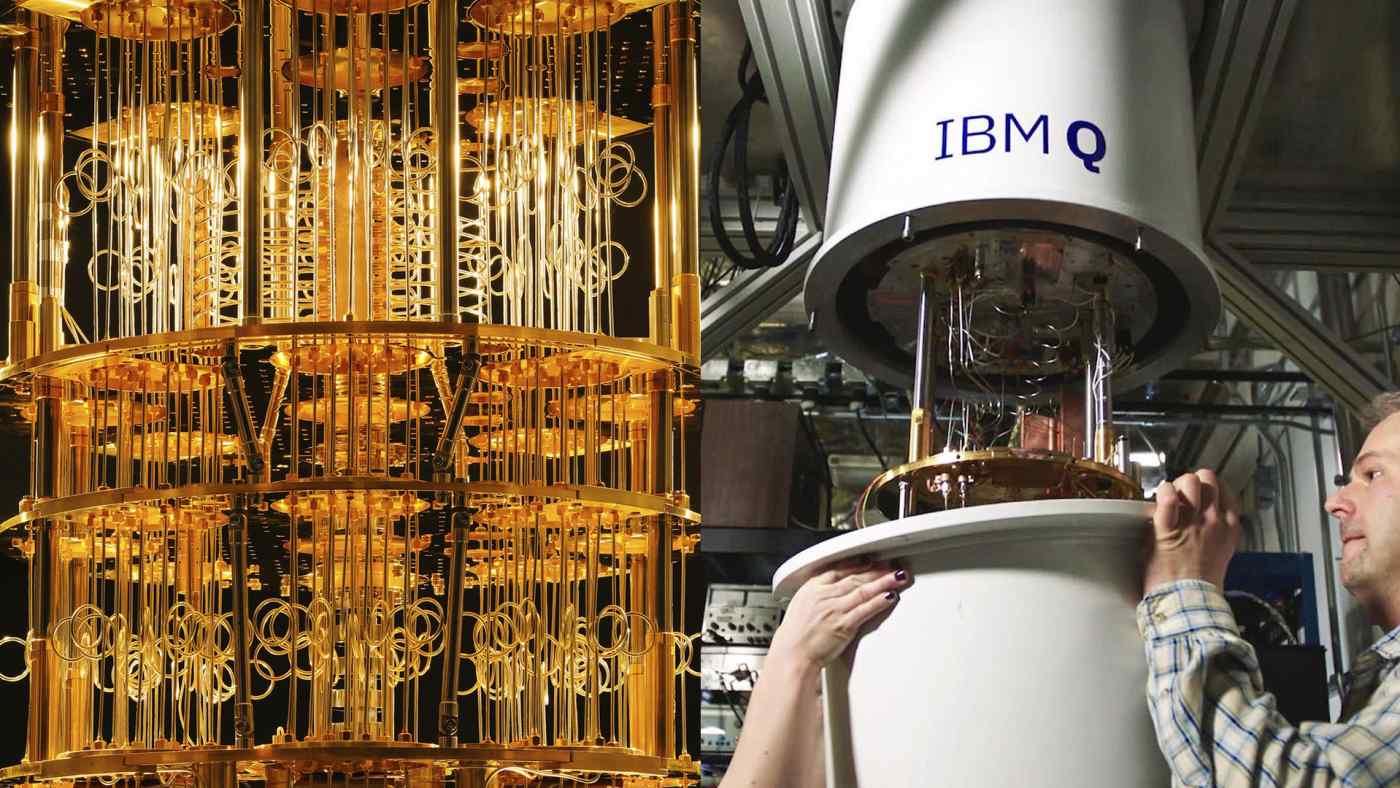

The goal is to realise lower error rates as well as higher analysing speeds. The two companies are expected to use Japan’s first commercial quantum computer, which was started up by the University of Tokyo and IBM in July.

QunaSys said it is focused on developing algorithms and applications that can be used in the field of material development.

Materials Informatics

Toyota Motor Corporation has been researching materials informatics, which is a new material design method, for a wide range of applications to mobility.

On Thursday, Toyota said its global production fell by more than a third in September from a year earlier, due to a shortage of semiconductors and other key parts.

The company produced 512,765 vehicles in September, down from 841,915 cars a year earlier, Toyota said in a statement. Global sales fell 16% for the month, the first year-on-year drop in 13 months.

“In September 2021, a parts supply shortage caused by the spread of Covid-19 in Southeast Asia resulted in year-on-year declines in global sales and production,” Toyota said.

“The situation remains unclear with respect to both Covid-19 trends and parts supplies, but we will continue to make every effort to minimise the impact.”

• By George Russell.

READ MORE:

Chinese Quantum Computers Outpace Western Rivals: SCMP

China Seeks First-Mover Advantage in Quantum Technologies