The world’s top chipmaker, Taiwan’s TSMC, is planning a second plant in Japan, with a goal of starting production by the end of 2027.

The group, formally known as Taiwan Semiconductor Manufacturing Company, said on Tuesday this second facility will bring its total investment in Japan to more than $20 billion, thanks to support from the government in Tokyo.

TSMC announced plans three years ago to build a $7-billion chip plant in Kumamoto in southern Japan’s Kyushu Island.

It said in January the first Japanese factory would open this month with volume production in the fourth quarter, and that the company was also exploring building a second factory in the country.

ALSO SEE: Huawei, SMIC Set to Defy US Sanctions With 5nm Chips: FT

In a statement, TSMC, the world’s largest contract chipmaker, said its majority-owned unit Japan Advanced Semiconductor Manufacturing in Kumamoto would build a second fabrication plant, or fab, in response to rising customer demand.

The second fab will begin construction by the end of this year and with both factories the site is expected to have total monthly capacity of more than 100,000 12-inch wafers to be used for automotive, industrial, consumer and high performance computing-related applications, TSMC said.

The capacity plan may be further adjusted based upon customer demand, it added.

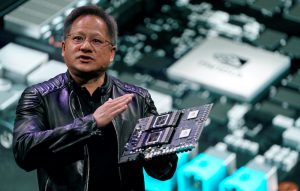

TSMC, a major supplier to companies including Apple and Nvidia, holds an 86.5% stake in the Japanese venture, with Sony Group 6%, auto parts maker Denso 5.5% and carmaker Toyota 2%.

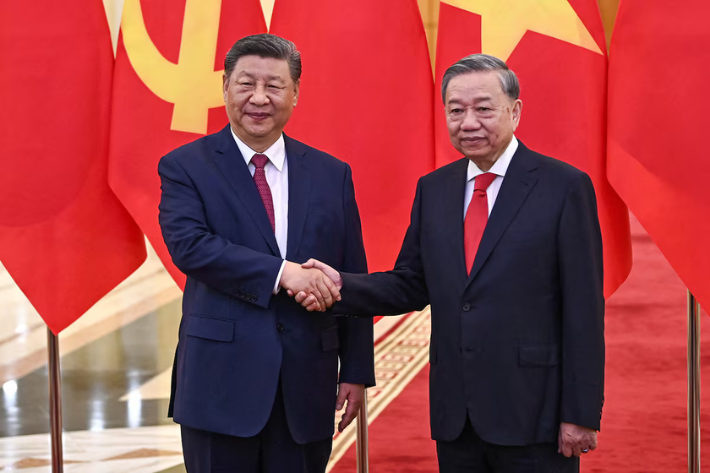

TSMC’s expansion in Kyushu is central to the Japanese government’s efforts to rebuild the country’s position as a leading chip manufacturing centre and ensure the stable supply of chips amid trade tensions between the United States and China.

Expansion running more smoothly in Japan than US

The decision to build a second fab is a vote of confidence by TSMC in Japan where construction of the first fab has run smoothly and which it sees as a source of diligent workers with a government that is easy to deal with.

Japan’s chip-making sector, the world’s biggest in the 1980s, has struggled to maintain its competitive edge, going into a steady decline in the past three decades, while rivals such as Taiwanese manufacturers gained ground.

While both TSMC and the Taiwan government have said the majority of the company’s most advanced manufacturing would continue to take place in Taiwan, TSMC has been expanding its global manufacturing footprint in response to what it says is customer demand.

TSMC’s flagship overseas investment is a $40-billion project to build two fabs in Arizona, supporting Washington’s plans to boost US chipmaking capacity.

TSMC is also planning a first European factory, in Germany, which will mainly supply the auto industry.

TSMC’s Taipei-listed stock has risen 8.9% so far this year on the back of a boom in demand for chips for artificial intelligence applications, outperforming a 0.9% gain for the broader index.

- Reuters with additional editing by Jim Pollard

ALSO SEE:

TSMC, Samsung May Bag Billions in Subsidies for US Chip Fabs

TSMC Gets China Chip Waiver From US, Eyeing ‘Permanent’ Permit

‘Frustrated’ in US, TSMC Finds Japan Chipmaking a ‘Natural Fit’

TSMC Seeks up to $15 Billion in US CHIPS Act Subsidies

TSMC Drafts in More Taiwan Workers to Speed Up US Fab Build

Arizona Workers Say Building TSMC Factory ‘Worst Job Ever’ – BI

High Cost, ‘Unmanageable’ US Staff Plague TSMC in Arizona – NYT

TSMC’s Tough Standards Could Hit Hunt for US Staff – Fortune