Startups in the US and Europe are rushing to develop cheaper batteries for electric vehicles (EVs) in a move that could lower China’s dominance in the industry and widen EV markets in major Asian countries.

They are aiming to replace some of the most expensive materials used in EV batteries with abundant and cheap materials — sodium and sulfur. If they succeed, they could create batteries that could be up to two-thirds cheaper than today’s lithium ion cells.

More than a dozen start-ups have attracted millions of dollars in investment, as well as government grants, to develop new kinds of batteries. Some of these include Berlin-based Theion, UK-based Faradion, and US-based Lyten.

Why cheaper EV batteries matter

Today’s EVs run on lithium ion batteries — mostly made with lithium, cobalt, manganese and high-grade nickel, whose prices have skyrocketed over the past two years. Current EV battery packs typically range in cost from $10,000-$12,000.

The EVs of the future — those arriving after 2025 — could shift to significantly cheaper sodium ion or lithium sulfur battery cells. This could potentially make EVs affordable beyond the middle class.

Also on AF: China EV Giants Revved Up For European Sales Drive

“Sodium ion definitely has a place, especially for stationary storage and low-end vehicles in cost-sensitive markets such as China, India, Africa and South America,” says consultant Prabhakar Patil, a former LG Chem executive.

Battery startups say they are talking to major automakers, some of whom are actively testing new batteries that could be on the road in mass-market EVs before the end of the decade. The car companies are keen to keep their options open.

“Over time, more (battery) chemistries will come out,” said Linda Zhang, chief engineer on Ford’s F150 Lightning electric pickup truck. “It would be silly not to take advantage of those chemistries.”

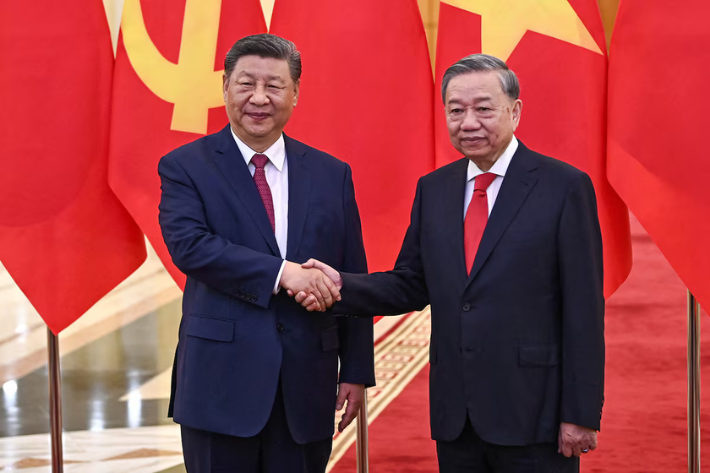

The China factor

Western producers are struggling to catch up with their Asian rivals, and carmakers expect supply bottlenecks to hit car production around the middle of the decade.

For now, China dominates battery production, including the mining and refining of raw materials.

Benchmark Mineral Intelligence, a UK-based consultancy, estimates China currently has 75% of the world’s cobalt refining capacity and 59% of its lithium processing capacity.

“We’re still dependent on a material supply chain from China,” said James Quinn, chief executive of British sodium ion battery startup Faradion, which received more than $1 million in government grants from Innovate UK before it was bought by Indian conglomerate Reliance last year for $117 million.

“If you look at the global geopolitical implications of that, it’s a challenge for energy security, economic security and national security.”

Also on AF: China’s BYD Planning Premium EV Brand Launch Next Year

Asian battery giants are also working on new chemistries. China’s CATL has said it plans to begin producing sodium ion cells in 2023. Korea’s LG Energy Solution aims to start making lithium sulfur cells by 2025.

Tony Harper, director of the Faraday Battery Challenge, the British government’s program that invests in fostering new battery technologies, said the automotive industry is increasingly worried about supplies of lithium, cobalt, manganese and nickel, so new chemistries are vital.

“This will take up the strain of what we thought would be a very, very difficult situation,” Harper said.

Challenges ahead

Newer battery chemistries have problems to be overcome. Sodium ion batteries don’t yet store enough energy, while sulfur cells tend to corrode quickly and don’t last long.

Duncan Williams, managing director of advisory Nomura Greentech, said recent discoveries are closing the gap on issues like energy density and cycle life, “so we would expect to see both of these alternatives taking market share in the future.”

Michigan-based Amandarry is already producing sodium ion cells at its plant in Haining, China.

Sulfur, meanwhile, is a “wicked hard chemistry” to make work in batteries, says Celina Mikolajczak, chief battery technical officer at California-based startup Lyten, which has attracted $47.5 million from investors.

But, she said, it is “the chemistry of the future, the chemistry that makes batteries mass market.”

Ulrich Ehmes, CEO of Theion — ancient Greek for sulfur — says the problem with sulfur is that it is so corrosive that it kills a battery after 30 charges. But he said the Berlin-based company has developed a way to treat and coat a lithium sulfur electrode that should make it last an EV’s lifetime.

Theion believes its lithium sulfur cathodes could store three times more energy than standard nickel cobalt manganese cells, charge ultra fast and cut battery cell costs by two-thirds, to about $34 per kilowatt-hour.

“It’s cheap, it’s high energy density so it seems to be a no-brainer,” Ehmes said.

- Reuters, with additional editing by Vishakha Saxena

Read more:

BYD Has Most EV Tech Patents of China Carmakers – Nikkei

Indonesia Will Launch $2-Billion EV Fund With China’s CATL

China’s Reliance on Foreign Battery Metals a ‘Risk to EV Sector’

Musk’s Tesla Struggles With Advanced Battery Production